|

|

Operation and Display

- Every 200 Series instrument relies upon the same operations protocol. A simplified, two button human interface system allows access to every function.

- On power up the instruments enters a primary display state. They may be operated permanently in this state or additional advanced features can be activated directly from the front panel.

|

|

|

Trend Graphing - Display real-time performance data in graphic form while still retaining the primary functionality.

- A variable time base can be selected to provide the exact data required.

|

|

|

External Alarm Output - 200mA sink output alarm that triggers on all alarm (red) conditions.

- All instruments may be interfaced to the CA200 instrument.

- To use any other annunciator device simply connect the ground of the device to the orange wire on the harness. Bus power is applied to the other side of the device. Any amount of 200 Series instruments may be "OR'd" to the single annunciator by connecting them together.

|

|

|

Certification

- Full certification as primary replacements

- FAA TSO

- Canadian STC

- FAA STC

- EASA STC

- Comprehensive EL/AML covering in excess of 900 aircraft models

|

|

|

Low Current Drain

- Requires less than 100mA.

- Works on all 14V and 28V aircraft systems. 6V-36V operation capability.

|

|

|

Zero Contact Senders and Probes

- Every signal is completely isolated from the aircraft systems.

- Thermocouples are ungrounded, eliminating ground loop issues common with the majority of other products.

- Temperature and pressure sensors are completely isolated from the aircraft while making contact with the measurable medium.

- Aircraft current measurements are made using an electrically isolated connection, protecting instrumentation from the harsh electrical system.

|

|

|

Simple Connection Interface

- A standard DB25 interface connector is provided on the rear of the instrument for easy installation and removal.

- Complete, fully built installation harness included with each kit.

|

|

|

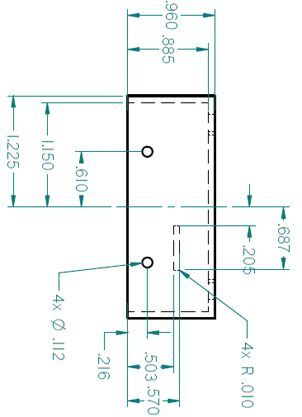

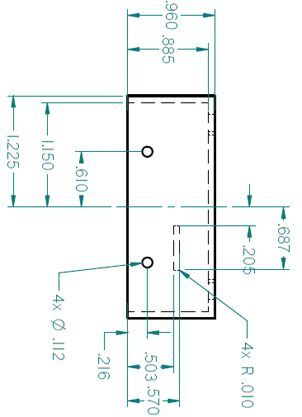

Tiny Footprint

Each instrument measures only 0.96" in depth (without connector). This allows for:

- Easier installations (more workspace behind the instrument).

- Much lower panel loading factor due to the reduced moment force on the panel face.

- Installation into reduced space locations that were previously not possible.

|

|

|

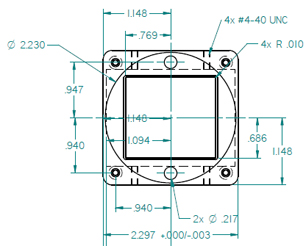

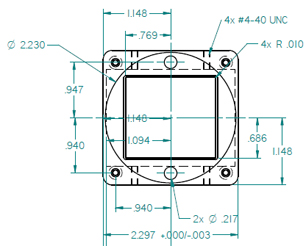

Standard Form Factor

- Fits a standard 2 ¼” aircraft mounting hole.

|